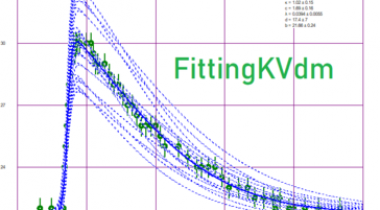

NWA Quality Analyst is an award winning SPC charting and analysis software solution providing the best combination of power, flexibility, and ease-of-use of any SPC software available.

NWA Quality Analyst

Customer Reviews

NWA Quality Analyst Reviews

Denzel Philip B.

Advanced user of NWA Quality AnalystWhat do you like best?

I like that the software is compatible with data from Microsoft Excel. This helps to make my job easier by allowing me to collect the critical data points on Microsoft Excel first and then copy / paste the date to NWA Quality Analyst. From there the software allows me to create various plots to analyze the performance of manufacturing processes of the company.

What do you dislike?

What I noticed is that the application is very prone to crashing and closing the program especially when I am looking between different windows on the computer. This can deter my work especially since it does not save the data automatically and I have to re enter the data that I had initially collected.

Recommendations to others considering the product:

When using NWA Quality Analyst, be aware that clicking between windows can lead the application to crash. So be sure to constantly save your work progress. Microsoft Excel can omplete the same task of collecting and plotting data, but NWA Quality haa better tools for analyzing the data and calculates ritical information from the data to provide a more complete report.

What problems are you solving with the product? What benefits have you realized?

Using NWA Quality Analyst, I am able to help my company improve manufacturing processes by finding trends in the nonconformance patterns. Analyzing and finding trends allows us to pin point the root cause for failure. From there, engineers conduct failure analysis to prevent repetition of the same mistake in future manufacturing of products.