A customized system for all types of maintenance management.

KMR integrates IoT technologies (Internet of Things)

focusing on automatically gathering information about equipment / machinery and other useful data for maintenance management: Operating time | Vibrations | Temperature | Level | Flow | Concentration

KMR maintenance management system provides you with accurate information due to integrated equipment sensors that colects valuable data for maintenance management process.

Factory managers can now access data such as: equipment efficiency, production line efficiency, alerts in case of an incident from any location, and more.

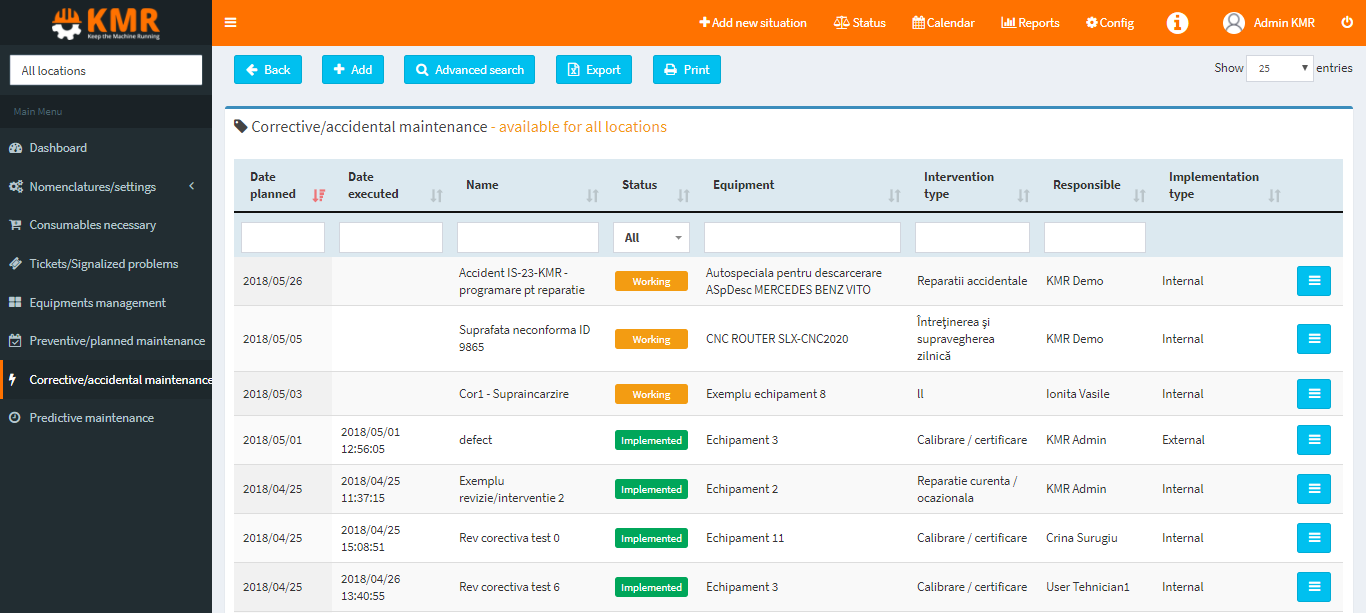

Preventive maintenance and predictive maintenance: Ensure continuous workflow of the equipment and reduce downtime. Prevent unexpected damage, reduce wear on dynamic and static components. Reduce overall maintenance costs by monitoring the technical condition of the equipment and its behavior over time in order to determine the maintenance needed since the first scheduled repair.

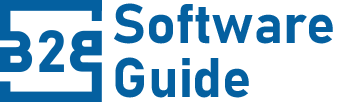

Reduce response time by assigning tasks to technicians (tickets / requests), evaluate your staff and write up activity reports. Delegate tasks in a balanced manner, effectively supervise employees activities and productivity.

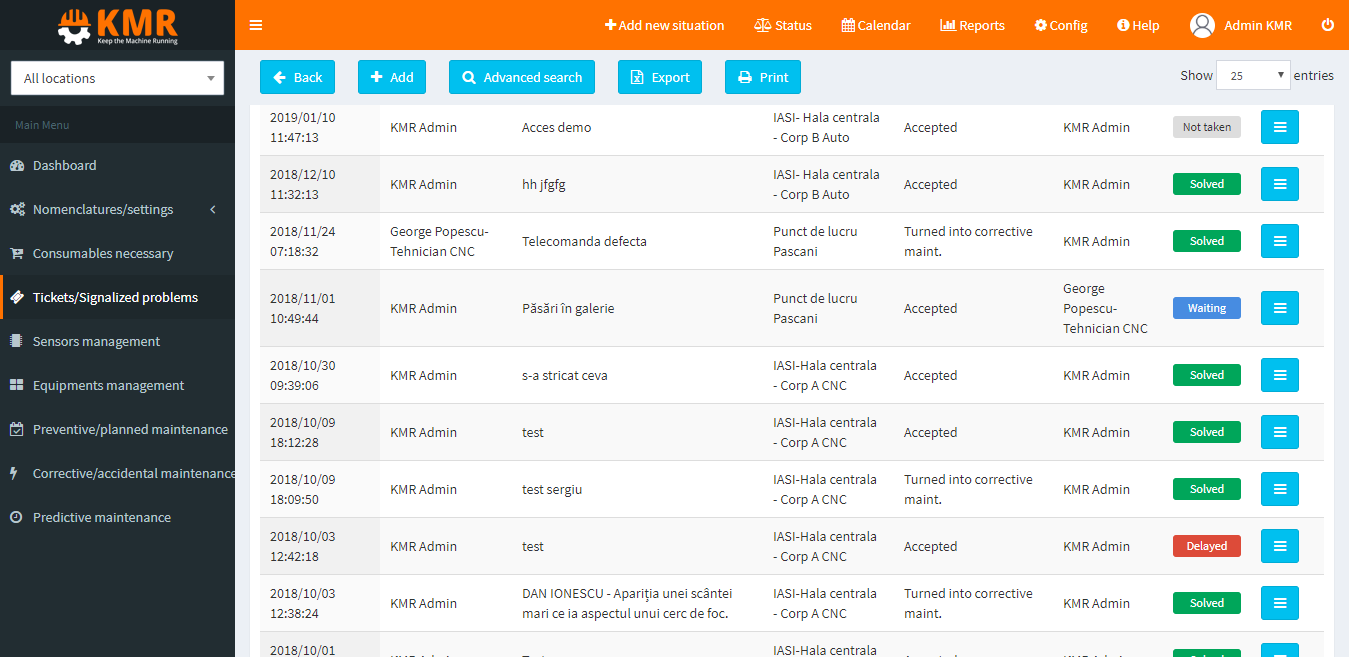

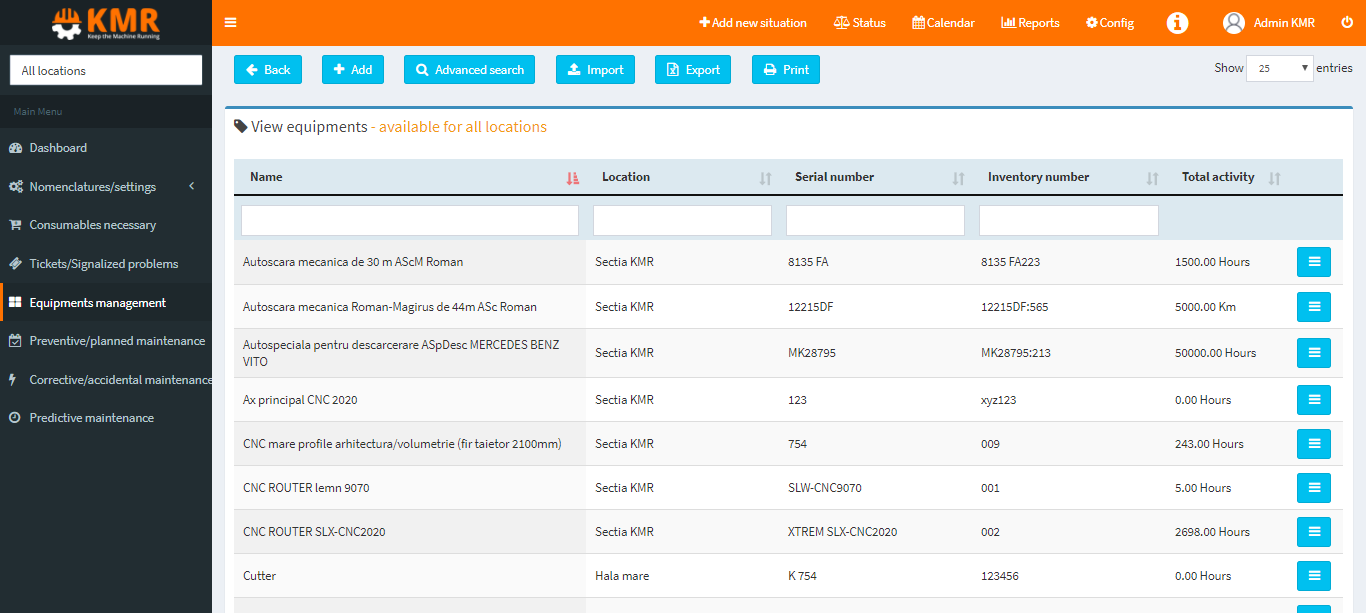

In addition to managing tickets, the simple scanning of the QR code provides, to authorized employees, access to equipment information, like: technical specifications, maintenance history, operating hours, status revision, user manuals and any other material required to fulfill the tasks.

The registered equipment in KMR system is associated with a unique QR Code, which once scanned allows logged technicians to begin solving assigned tickets for each machine. Thereby, each employee activity and ticket status is registered.

Increase the speed of workflows by configuring alerts and notifications. Simplify the process and increase the speed of working interventions. You have real-time access to information / decisions, you are sure that accurate and detailed information is passed on to the right people, at the right moment.

Analyze and make decisions based on application-specific reports, extremely useful information for: management, economic department and maintenance management department.

Validate the quality of work. You can quickly detect equipment with frequent malfunctions, identify abusive or irrelevant actions, determinate which areas give the best results, and which areas record losses.

Manage inventory and budget reporting based on needs.

You can find information about equipment efficiency or inefficiency based on those that produce the most maintenance costs (top spending, top usage, top revisions etc.).

Optimize your employee’s work and production using predictions.

Analyze the impact of implemented measures.

Prove your company efficiency in management and production to attract new contracts.