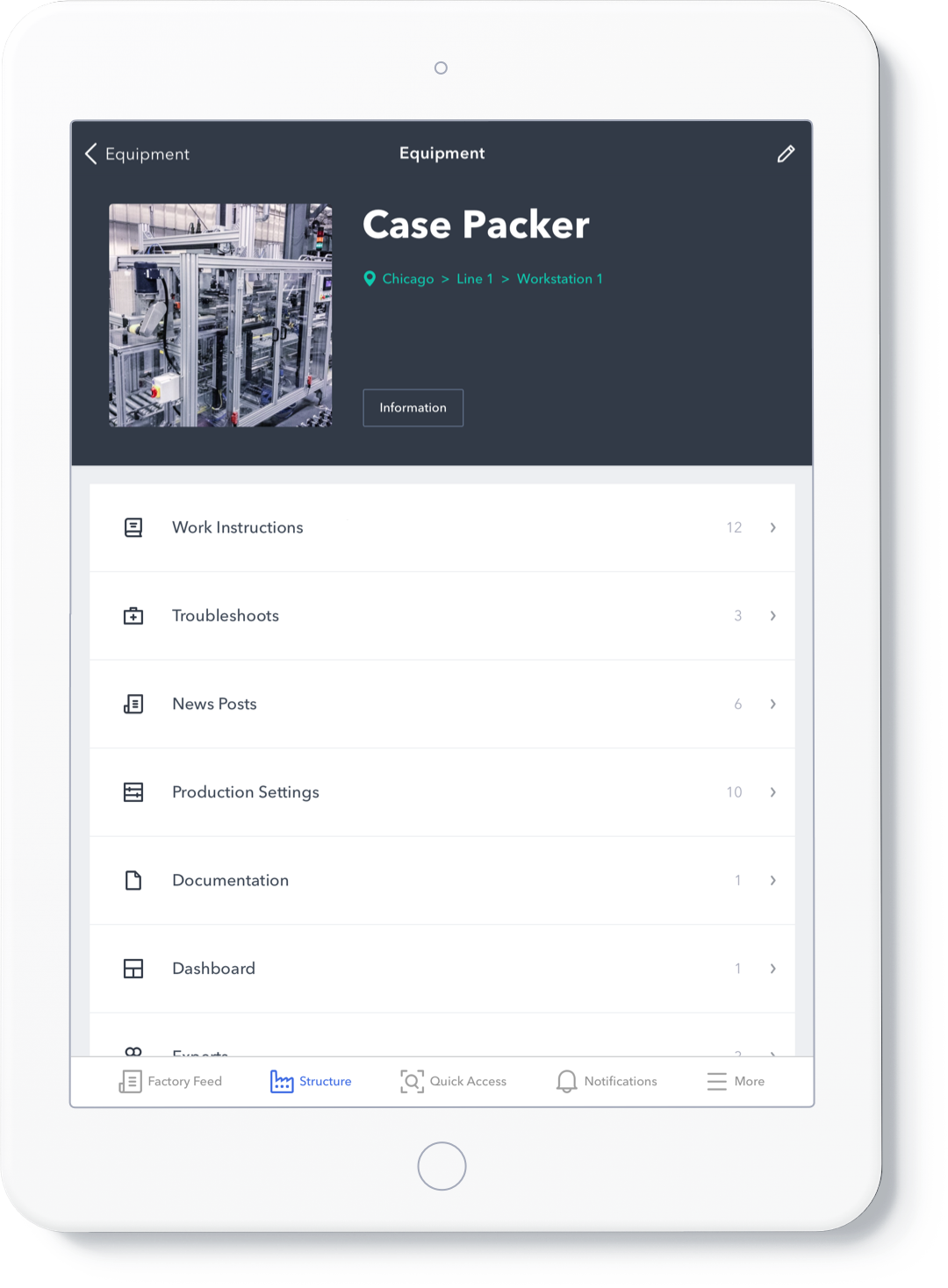

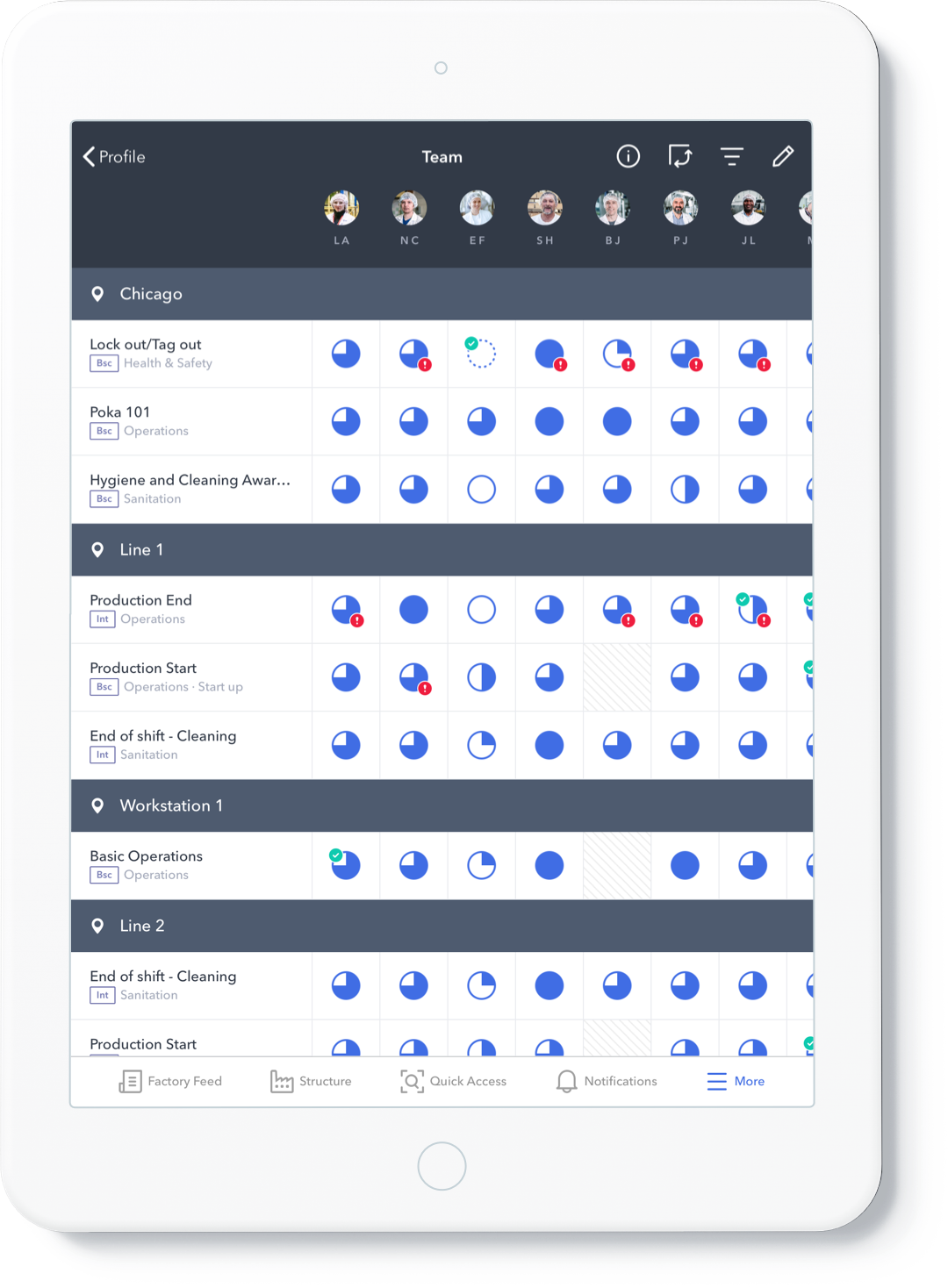

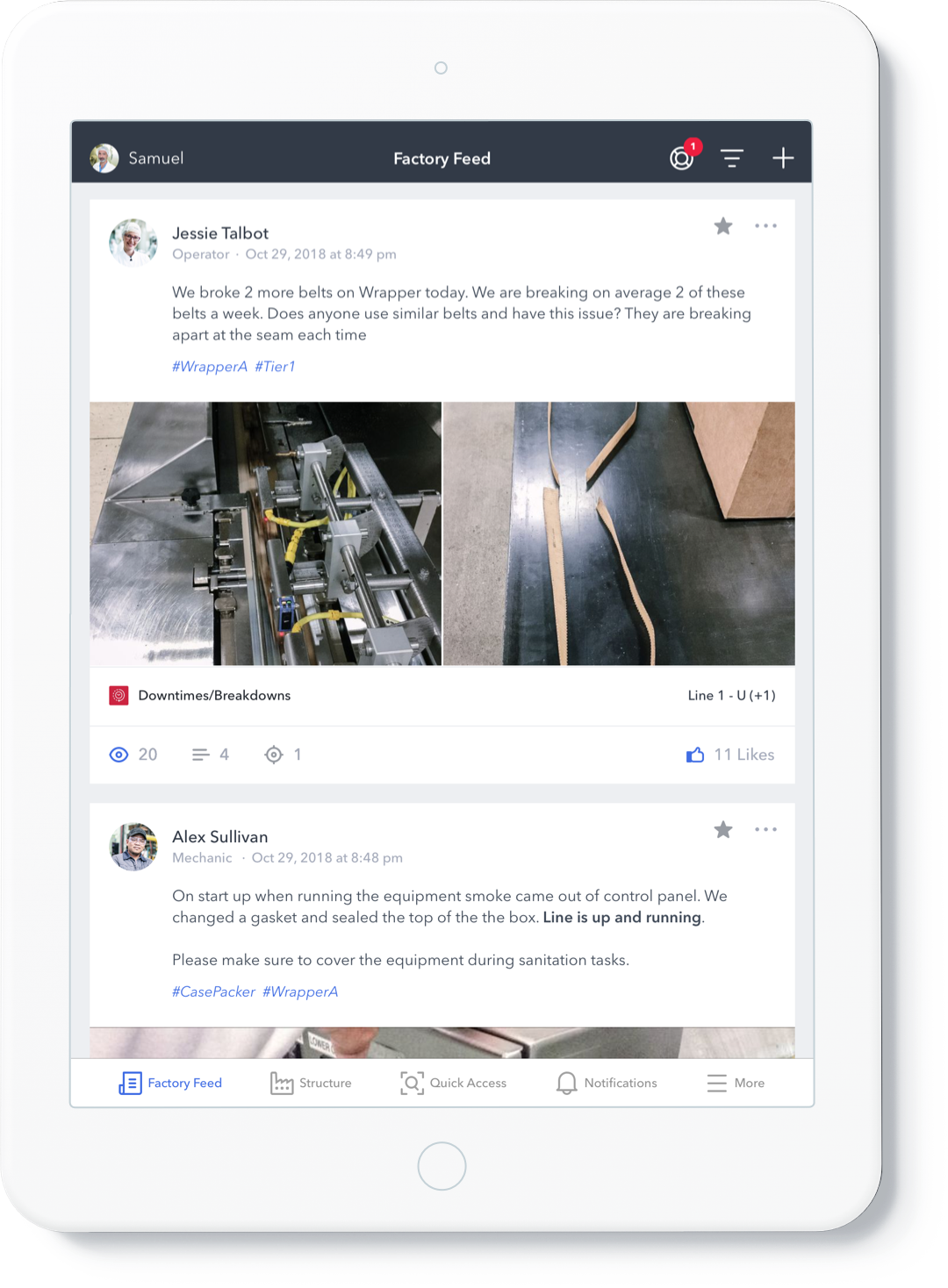

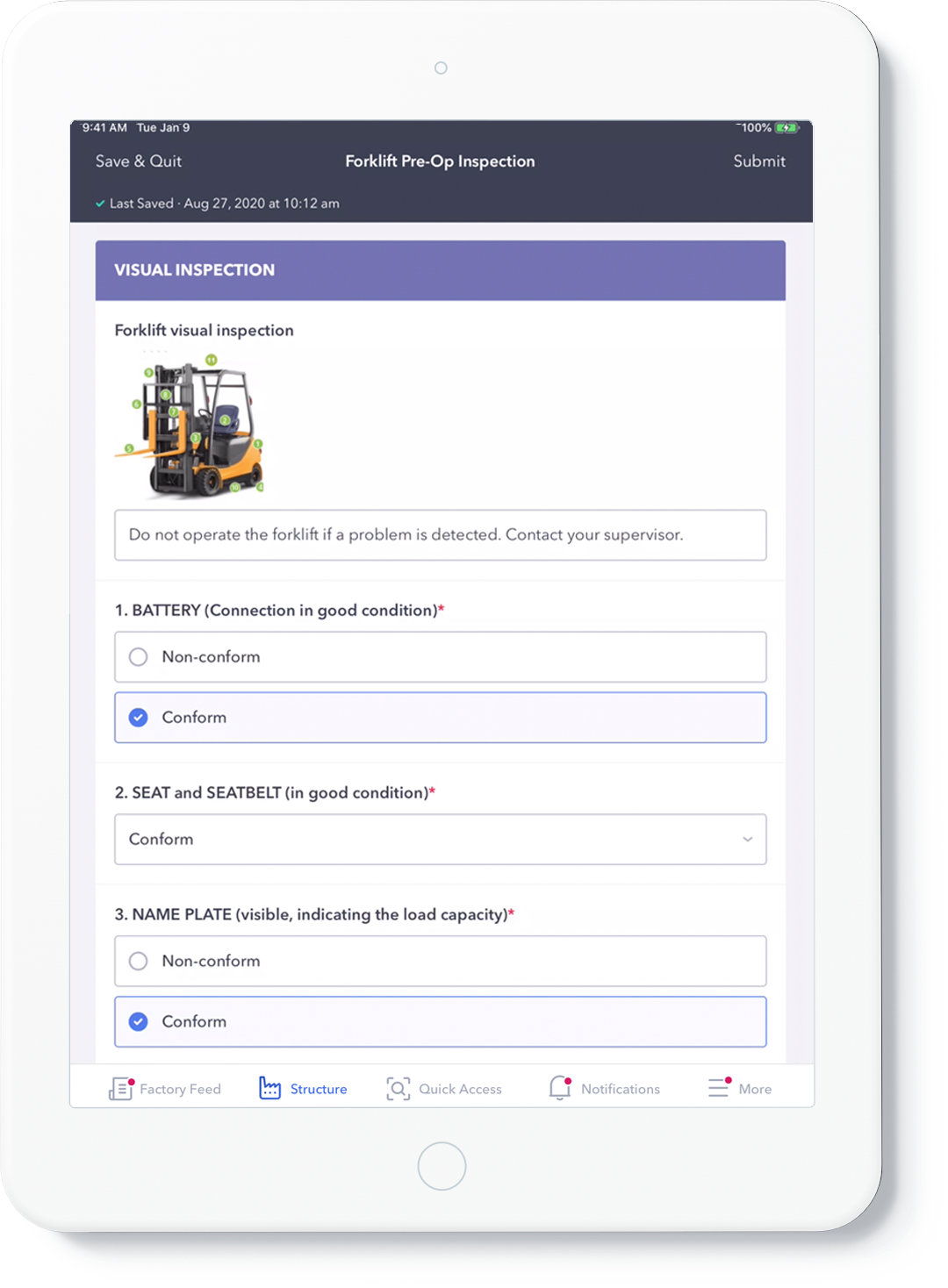

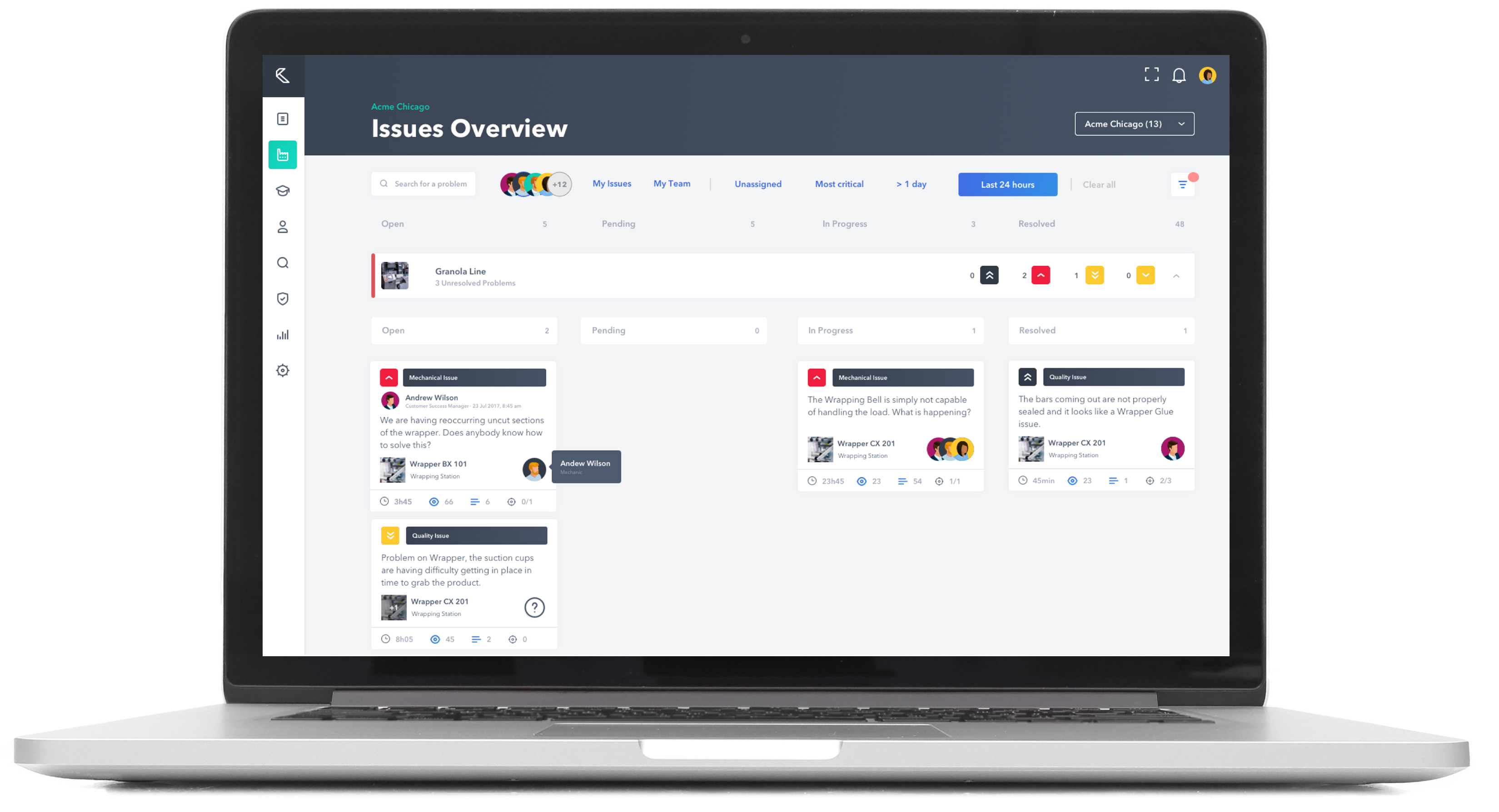

Poka is a connected worker application built for manufacturers. With Poka, factory workers are empowered to learn continuously, solve problems and share knowledge in real-time directly on the production floor – fostering an engaged and autonomous workforce that drives improvements in safety, quality and productivity. Poka combines digital content, communication, forms and skills management capabilities into a single integrated platform, leading to a better user experience and stronger adoption and value. Poka is trusted by digital manufacturing leaders including Bosch, Kraft, Danone, Mars, Stanley Black and Decker, and ABB.

Poka.io

Images

Check Software Images

Customer Reviews

Poka.io Reviews

Gabriel A.

Advanced user of Poka.ioWhat do you like best?

Profiling user's behaviors to identify how to develop the organization.

What do you dislike?

Not transparent features pipeline. When a new feature is requested and inserted in the pipeline, it's not clear if it will be developed and by when.

Recommendations to others considering the product:

Not a digital upgrade, but a transformation. Poka brings efficiency and efficacy promoting a positive impact to the organization culture.

What problems are you solving with the product? What benefits have you realized?

Production planning last status directly presented to the shopfloor (increased adherence schedule).

Shift handover and trainings on POKA (reduced overtime and supported social distancing during COVID).

Profiling behaviors (understanding why one has a type of behavior, how we can develop them and what will be the outcomes).

Optimizing problem solving (better and faster analysis allowing the maintenance team to solve more problems and improve the sustainability of the actions).

Info sharing (several departments using the platform to directly share news to the operations overcoming the COVID social distancing challenge).

Process standardization with work instructions reducing overprocessing and defects wastes (~ 100 kUSD/year of benefits).